OEM/ODM China Child Resistant Metal Box - Three-pieces Hinged Tin Box – CR

OEM/ODM China Child Resistant Metal Box - Three-pieces Hinged Tin Box – CR Detail:

Description

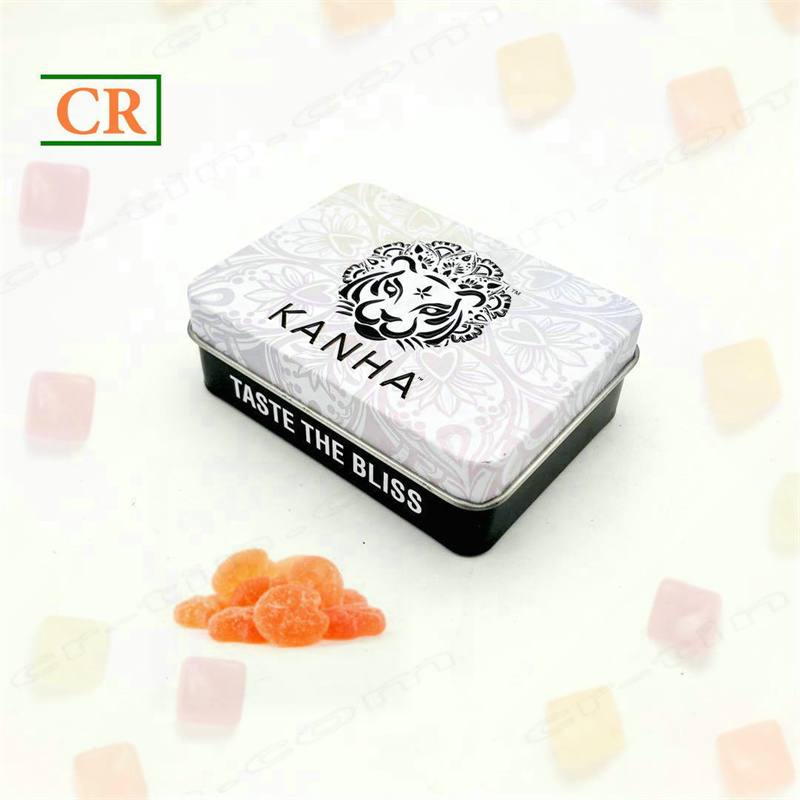

It’s three-pieces tin structure – lid, bottom and body. The rolled outside lid, the rolled inside body and rolled inside bottom forms this flat tin. It applies a pin as hinged area, not the original tin area that ensures the strong connection between lid and body. The structure of this tin mold could be improved to automatic production line easily to keep the faster produing with best quality. There is no limit for artwork for this tin structure and the flat lid could achieve the larger embossing area.

Gummies Hinged Tin Box

Custom Printing

Various Usage

Three-pieces hinged tin box has various advantages for gummies packaging. Flat lid and bottom provide more areas for embossing or debossing, pin hinge ensures the half opening to take out gummies easily, rolled inside body packs and protects gummies well, rolled outside with rolled inside body keeps the pretty apperance – coordinating tin size.

All the artwork and embossing could be applied to this gummies hinged tin box. Putting the artwork in template and then printed tin samples will be finished after 10 days. Matt finish background with gradient ramp artwork will display the attractive appearance maximum.

It’s designed for gummies or edibles packaging. The food grade material allows the gummies could touch tin directly. Usually, packing gummies will increase a printing butter paper in tins.

Product detail pictures:

Related Product Guide:

CR Tin doesn’t produce tin box directly, but they equip more factories’ advantage like various certified child resistant tins, customized CR tin ability, lower cost, premium quality, faster production. CR Tin specializes in child resistant tin’s developing, tin mold, CR testing and production, delivery that provides one-stop service. There are at least 10 different child proof structures that could be applied to all kinds of child resistant tins. Various existed child resistant tins with certification could cover all kinds of cannabis product’s package. Faster customized ability ensures the certified child resistant tins could be finished within one and half month from an idea to certified child-proof tin version. CR tin provides child resistant solution for metal packaging, opens tin mold and then transfer tin mold to factory with strict quality control standard that could ensure this child resistant tins wouldn’t be copied in the market and with the lower cost, the faster delivery time and the standard quality. Unlike the other suppliers, CR Tin insists on the recycling material for all kinds of child resistant tins that utilizes the original tinplate to form the stable CR tins and CR Tin is the first Chinese company who has various CR tins with US CR certification. Any requirement for child resistant tins, CR Tin will provide various options with reasonable cost to save more your cost and time. CR Tin – your reliable partner on CR tins. OEM/ODM China Child Resistant Metal Box - Three-pieces Hinged Tin Box – CR , The product will supply to all over the world, such as: Cyprus, Cannes, United Kingdom, How to pack the smaller jellies? It needs the customized smaller child resistant tin to pack it. There are two tins to pack jellies from CR Tin, rectangular hinged child resistant tin 77x34x18mm and square child resistant tin 32x32x32mm. They are different structure for jellies packaging. Rectangular child resistant tin box 77x34x18mm applied hinged Gen2 child resistant lock that the hidden lock achieves the smooth appearance and the compact tin size makes tin portable. Unlike the large tin size, rectangle tin box could pack 10 jellies only that belongs to the smaller quantity version. Child resistant tin cube 32x32x32mm is the new child resistant mechanism that using two slots on lid to hold the edge of tin bottom with this three-pieces structure, the child resistant lock is Pushing & Lifting style, so the opening method will be pushing one side of slots area and then lifting tin lid. Usually, it packs 1-3 jellies. Unlike Gen2 version, this tin cube could be applied to all kinds of child resistant tin size and shape. The airtight version for this tube needs the resin to make up the defect of structure. Two jellies metal box could be packed with shrink wrapping as disposable air tight method.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

Products categories

CONTACT US

Please get in touch to order !

-

Whatsapp

-

WeChat

WeChat

-

Ins

Ins

-

Top