Small Tin - China Factory, Suppliers, Manufacturers

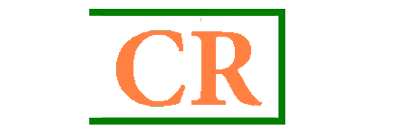

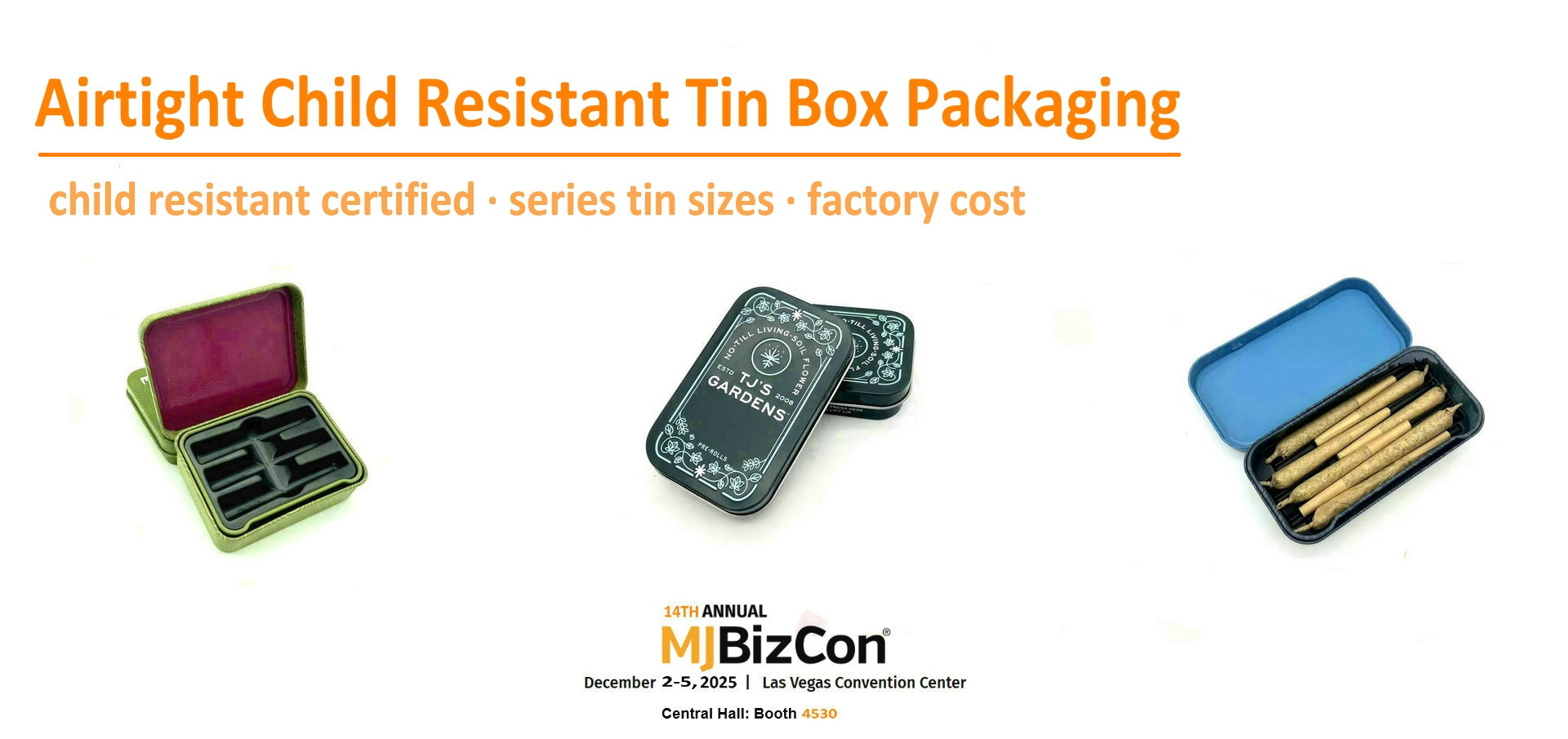

Round child proof tins are the regular CR tin in the market. Most CR mechanisms of round child proof tins belong to Press & Turn with screw. It’s the same as plastic child resistant bottle that belongs to the classical design for pills in many years ago. In order to achieve childproof lock, some companies chose three-lids structure, some companies chose tin with plastic lid or two-lids with accessories. But CR Tin developed a new method to make their round child proof tin to be Lift & Turn. It’s one-piece lid structure that the slot area in the necking of tin body passes through the gap of lid area. This child proof lock could keep the exquisite and smooth appearance with lower cost. Small Tin, Small Tin Gift Boxes , Flower Child Resistant Tin Box , A Tin Box ,Tin Can Candy . Press & Turn is common lock for round child proof tin in the market, but CRALD7625 uses the original tinplate structure to form Turn & Lift child proof mechanism that changes the four-piece to up-bottom structure and save more the cost. The rolled inside lid and bottom forms this hidden child resistant lock with the elastic tinplate to create this stable child proof tin can. CRALD7625 applies slots and grooves lock style to consist of child proof mechanism that two slots on necking area of bottom lock the rolled inside lid that the lid could be released when two slots pass two grooves on lid. This structure would reduce the unit cost with the exquisite appearance that is new option for round child resistant tin can. As this up-bottom structure of this child proof tin can, it could be improved to airtight version easily that adding a silicone gasket on lid would be working perfectly (airtight means under water and no water in tins). the child proof lock wouldn’t be affected by silicone gasket and it could match child proof lock well. It belongs to recycling airtight child proof tin can in the market that the lighter weight, lower unit cost, good-looking, assembling easily forms this popular certified airtight child proof tin can. The product will supply to all over the world, such as Europe, America, Australia,Rio de Janeiro, Lebanon,Ukraine, Ukraine.The classical hinged tin box 100x60x20mm is chose by most of larger customer. Hinged structure protecting mints well, different tin size meeting the requirement of difference volume, traditional opening style calling more memories, larger space taking out mints easily, these advantages form this tin to pack mints appropriately. Comparing slide tin case, hinged tin box has larger space to meet the larger volume of mints.

Related Products

Top Selling Products

CONTACT US

Please get in touch to order !

-

Whatsapp

-

WeChat

WeChat

-

Ins

Ins

-

Top